Customized Safety Training Strategies for Regulatory Required Training and More

One of the best methods for improving production, quality and employee safety is to ensure that employees are properly trained prior to being placed in the production process. It doesn't help any organization to have the best equipment and process flow, if the employees are not trained on the proper procedures and safe guards associated with the operation.

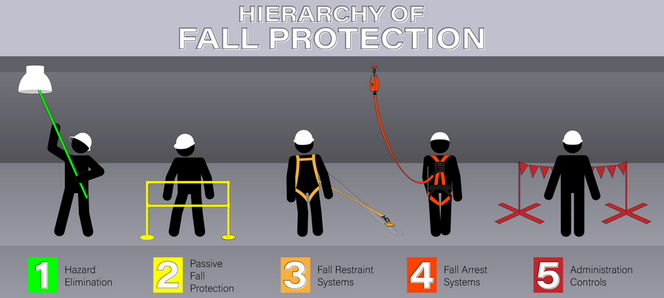

Our training modules are designed to allow employee training when time is available. We will help you develop a customized safety training strategy, which will include industry, OSHA and regulatory required training.

Safety Resources, Inc. is a 100% woman owned and controlled business certified with the city of Indianapolis, the state of Indiana, the Women's Business Enterprise National Council, and INDOT DBE certified.

Safety Resources, Inc. is a 100% woman owned and controlled business certified with the city of Indianapolis, the state of Indiana, the Women's Business Enterprise National Council, and INDOT DBE certified. Safety Resources, Inc. is accredited by the International Association for Continuing Education and Training (IACET) and is accredited to issue the IACET CEU. Our qualified trainers will work with your company to develop a customized course or

Safety Resources, Inc. is accredited by the International Association for Continuing Education and Training (IACET) and is accredited to issue the IACET CEU. Our qualified trainers will work with your company to develop a customized course or