Summer has officially started, the heat is on, and 2018 has already proven to be a record breaker with May going down as the hottest month of May in Indianapolis on record. That makes heat stress and heat related illness a great topic to consider as we move into the heat of the summer.

There’s a certain irony about heat stress when recognizing it as a workplace hazard. Rarely is it found on the company job hazard analysis forms; it’s not a hazard that can be seen, heard, smelled, etc. But when the heat is on, it’s on, and employers must be capable of recognizing heat stress and mitigating it in a flash, because an employee who’s not prepared for the elements can be down and out for the count in less than an hour. So, despite the fact that it can’t be seen heard or smelled, heat can be a hazard, and employees must be trained on controlling this hazard, just like they would any other.

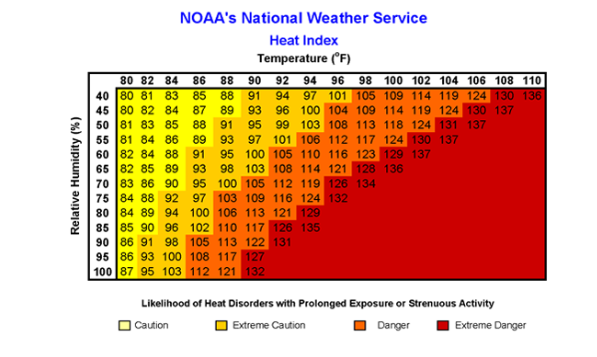

In addition to training employees on heat stress, overall risk can be reduced if all levels of an organization are capable of recognizing circumstances when the hazard is present and provide reasonable and flexible responses when it is. Obviously, anyone can recognize that it’s hot, but employers must be capable of recognizing how and when the heat is likely to affect their operations and what they may be able to do about it, or they run the risk of severe injury to an employee that has been over exposed to the elements. The humid air here in Indiana makes it even harder for the average employee working in a hot environment to simply sweat their heat away. When the humidity is high, it will evaporate off the employee less, and the sweat just tends to stick around, and soak into already hot clothing, or PPE, but all the while the fluids inside of your body are going out of it. This is just part of the reason why OSHA recommends considering the heat index, a combination of the ambient air temperature and the relative humidity when determining when employees are at increased risks for heat stress / heat illness.

OSHA has broken down its heat risk analysis into four different levels:

The Lower Risk Level

When the heat index is less than 91˚F employers should take basic heat safety and planning precautions which includes ensuring that adequate amounts of drinking water are available in convenient and visible locations in the work area, as well as ensuring that medical services are readily available (OSHA’s recommendations are that if emergency medical services are more than 4 minutes away, an employer should have a first aid trained employee on site). It’s worth noting however, that these initial precautions are actually not solely reserved for heat stress, and are actually mandated by OSHA at all times for any workplace that falls under OSHA’s scope of authority.

The Moderate Risk Level

When the heat index is between 91˚F and 103˚F OSHA recommends beginning to implement specific heat related precautions, which includes but is not limited to:

-

Reminding and warning workers about the high heat, and increased risk for heat related illness,

-

Reminding workers to drink small amounts of water, often (about 4 cups of water every hour),

-

Acclimatizing new and returning workers to the job (as they may not be ready for the new work they are tasked with, let alone the extreme temperatures),

-

Allow regular and frequent breaks in the shade, or if possible, in an air conditioned room (supervisors, you can get a better bang for your buck on that job trailer, while mitigating risk at the same time),

-

And very importantly, respond to heat stress and heat related illness in a serious and hasty fashion. The worksite is never the place for machismo; encouraging an employee who may be complaining of heat stress related symptoms to toughen up won’t get the job done any quicker; and failing to properly respond to the employee’s symptoms can quickly become a fatal error.

The High Risk Level

When the heat index is between 103˚F and 115˚ F OSHA recommends implementing additional, specific, heat related precautions. This includes but is not limited to all of the items listed above, as well as:

-

Actively reminding workers to drink small amounts of water at least every 15-20 minutes, as well as providing cool drinking water to drink,

-

Establishing and enforcing work rest periods (as opposed to just reminding employees to take breaks, require them to, aka administrative controls),

-

Adjusting work schedules (to earlier in the morning, later in the evening, whatever works to allow for cooler shifts),

-

Not allowing un-acclimatized workers to perform strenuous tasks,

-

Provide workers with personal cooling measures including cool wet rags, or vests stuffed with cold packs,

-

And having a knowledgeable person onsite whom is well-informed about heat related illness and authorized to modify work activities.

The Very High Risk Level

Finally, when the heat index surpasses 115˚F OSHA recommends extra measures in addition to the precautions listed above to protect workers. This includes but is not limited to:

-

Rescheduling all non-essential outdoor work for days with a reduced heat index,

-

Not allowing workers to engage in strenuous tasks or tasks that require the use of heavy / non-breathable / impermeable chemical protective personal protective equipment or clothing,

-

Setting up a buddy system to ensure workers are watching out for each other,

-

And even, actively monitoring workers for heart rate, temperature, and other signs or symptoms of overexposure to the elements.

Employers should also take a moment to familiarize themselves with what the symptoms of heat related illness are. Information related to symptoms, the above heat index risk levels, and a whole host of other useful topics can be found at OSHA’s Heat Illness Prevention Campaign website, linked below. Included on the website, is a heat index chart (also pictured below) for readers to check out; also remember that many local news stations will report the index on broadcasts or mobile apps.

Realistically, Kool Aid and other sugary or caffeinated drinks may not be the best liquid to provide for employees, as they may have adverse health consequences (especially caffeinated ones, and especially in the heat), but Kool Aid is certainly better than nothing at all. So when the heat is on, always remember to drink plenty of fluids and be prepared for the elements.

OSHA Heat Illness Prevention Campaign – Using the Heat Index: A Guide for Employers

https://www.osha.gov/SLTC/heatillness/heat_index/index.html

Related Topics: Monthly Safety Topics, Safety Articles, Heat Safety, Summer Safety, Workplace Safety