Fatalities from falls, slips, and trips increased 5.6 percent in 2021, from 805 fatalities to 850. Construction and extraction occupations accounted for 370 of these fatalities. Despite the increase, this is still down 9.3 percent from 2019. Working at Heights and the utilization of fall protection systems continues to be an area of concern year after year as it is consistently in OSHA’s top 10 most frequently cited violations, as well as being the leading cause of work-related injuries for the past 10 years. Due to this consistency, on May 1, 2023, OSHA implemented a National Emphasis Program (NEP) with the focus to identify and to reduce hazards which are causing or likely to cause serious injuries and fatalities from falls while working at heights.

Raising awareness on common work place violations and slip, trip, and fall hazards as well as reporting methods for these conditions can help prevent falls from heights in the work place. One of the most important methods to prevent injuries is training with hazard recognition. It is required by OSHA that employers must “provide a training program for each employee who might be exposed to fall hazards. The program shall enable each employee to recognize the hazards of falling and shall train each employee in the procedures to be followed in order to minimize these hazards.” This also includes the correct procedures for erecting, maintaining, disassembling, and inspection of the fall protection systems to be used.

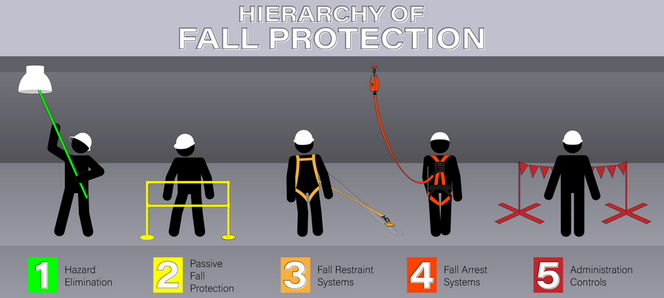

Two of the most common types of fall protection utilized are personal fall arrest systems (PFAS) and fall restraint systems. It is important to be able to identify and understand the differences between the two to be able to incorporate an applicable fall protection system to protect workers working at heights. A fall restraint system prevents the user from falling any distance, the system does not allow the worker to reach any unprotected side or edge. Typically, these systems have shorter connections and are adjustable to be restrictive. This could include an approved lanyard and anchorage point that must support up to 5,000 pounds per employee. There are also passive fall restraint systems that physically do not allow the worker to reach the potential hazard which include guardrail systems and flagged warning line systems. A personal fall arrest system (PFAS) is a system designed to arrest the fall and the impact involved in a fall from heights. This system does allow the fall to occur. These systems are equipped with a shock absorber which arrests the force put on the worker’s body. OSHA requires the max arresting force on the employee to be limited to 1800 pounds. With the proper usage of a personal fall arrest system this number can be cut in half to limit the max arresting force to 900 pounds. It is also required that these systems are equipped with the proper labeling to ensure the weights limits & restrictions are available.

It is critical that employers train their employees to understand the fall hazards associated with the scope of work as well as an understanding of applicable fall protection systems and when to implement them. Employers should focus on training their employees to be able to understand the proper functions of these systems to ensure their workers are protected while working at heights. The integration of a training program coupled with a field audit process to identify deficiencies to ensure the information received in training translates to the field is a step in the right direction to help prevent fall protection from being in OSHA’s top 10.

Related Topics: Jobsite Safety, Monthly Safety Topics, Fall Protection